How to Choose the Right Borescope Camera for Your Industry

Equipment failures happen when you least expect them. A crack develops in a critical component. Water damage spreads behind walls. Production stops because someone missed a defect during inspection.

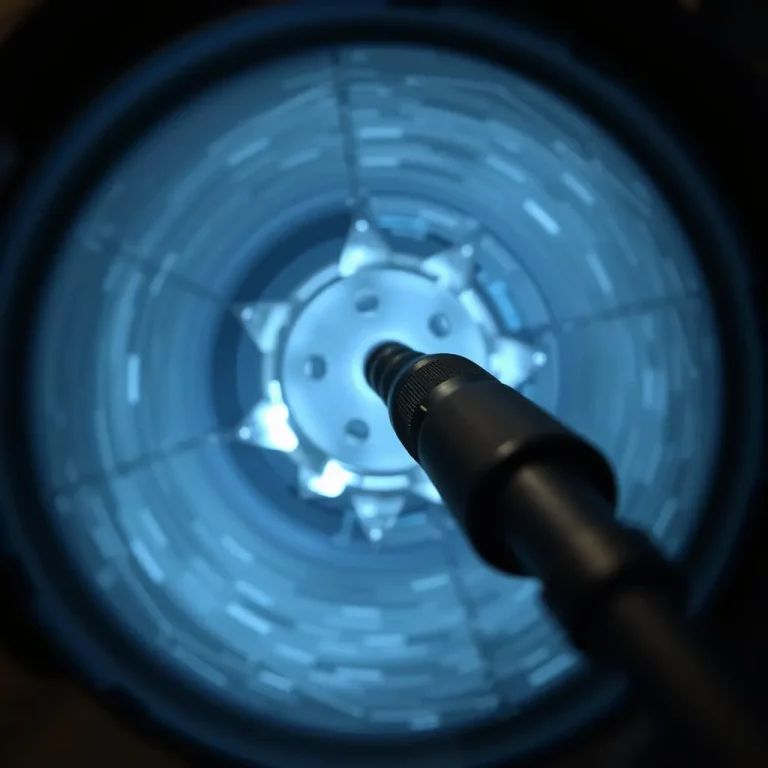

These situations create massive headaches for professionals who rely on visual inspections. The right borescope camera can prevent these disasters, but picking the wrong one might make things worse. You end up with blurry images when you need crystal-clear details, or equipment that breaks down right when deadlines are tightest.

The tricky part about borescope camera selection is that different industries have completely different needs. What works great for checking car engines might be totally wrong for aircraft maintenance. This creates confusion when shopping for equipment, and confusion leads to expensive mistakes.

Why Getting This Wrong Costs More Than Money

Bad inspection equipment doesn’t just waste your initial investment. It creates a domino effect of problems that can destroy careers and businesses.

Consider what happens in aviation maintenance. Missing a small crack in an engine component can lead to catastrophic failure. The investigation that follows will scrutinize every tool used during the inspection process. If your borescope camera couldn’t capture the detail needed to spot the problem, you become liable for the consequences.

The same principle applies across industries, though the stakes vary. Plumbers who miss pipe damage end up dealing with flood claims. Manufacturing quality control teams face product recalls when defective parts slip through inspections.

The cost of buying proper equipment seems expensive until you calculate what happens when substandard tools fail to do their job.

Resolution Numbers Can Mislead

Higher resolution sounds better on paper, but real-world performance depends on many other factors. Marketing departments love promoting 4K capabilities, but the actual benefits depend on the specific application.

File storage becomes a problem with ultra-high resolution systems. Each inspection might generate dozens of images and videos. 4K files consume storage space rapidly, and many facilities lack the IT infrastructure to handle this data volume efficiently.

Processing power requirements increase too. Older tablets and display units struggle with 4K video streams, causing lag and reduced frame rates. The inspection process slows down when equipment can’t keep up with data demands.

Battery life suffers with higher resolution systems. More pixels require more processing power, which drains batteries faster. This creates problems during long inspection sessions or when working in remote locations without charging options.

Probe Design Makes or Breaks Performance

The camera head and insertion cable design determine whether the equipment works in real-world conditions. Specifications sheets don’t capture how probes perform when pushed through tight spaces or exposed to harsh environments.

Articulation mechanisms are particularly vulnerable to failure. The joints that allow probe bending contain small moving parts that wear out over time. Cheap designs lose their positioning accuracy or bind up completely after moderate use.

Cable construction varies dramatically between manufacturers. Some use single-strand fiber optic bundles that provide excellent image quality but break easily when bent. Others use more robust multi-strand designs that sacrifice some image quality for durability.

Diameter considerations are often overlooked during equipment selection. A probe that measures just one millimeter larger might not fit through critical access points. Once equipment arrives on site, these dimension problems become expensive to fix.

Wireless Technology Has Limits

Wireless borescope cameras eliminate cable management problems, but they introduce new complications that many users don’t anticipate.

Signal interference is common in industrial environments. WiFi networks, Bluetooth devices, and radio frequency interference can disrupt wireless connections. When inspections are time-critical, connectivity problems create serious delays.

Battery management becomes a constant concern. Both the camera probe and display device need power, and coordinating charging schedules requires planning. Wired systems draw power from the display unit, eliminating this complexity.

Video lag affects precise navigation in tight spaces. The delay between camera movement and screen display might only last milliseconds, but this becomes noticeable when threading probes through complex pathways.

Range limitations are rarely mentioned in marketing materials. Most wireless borescope cameras work reliably within 30 feet of the display device. Longer distances cause signal dropout and connection instability.

Final Take

Equipment selection starts with understanding exactly what types of inspections the system needs to perform. Generic requirements lead to compromise solutions that don’t excel at any particular task.

Consider the complete system rather than just the camera component. Display quality, software functionality, and accessory availability all affect daily operations. The cheapest camera head might require expensive display upgrades to function properly.

Plan for growth and changing requirements. Equipment purchases often need to serve multiple purposes as businesses expand. Buying slightly more capability than is currently needed provides flexibility for future applications.

The right borescope camera becomes an investment in quality, safety, and professional reputation. Wrong choices create ongoing problems that compound over time, while proper equipment pays for itself by preventing expensive failures and maintaining inspection accuracy.

Featured Image Source: https://borescopehq.com/wp-content/uploads/2025/07/What-Is-an-Articulating-Borescope-768×768.webp

Kieran Ashford writes about personal branding and professional development for entrepreneurs. He offers guidance on building a strong personal brand to support business growth.